The blog of blasting

The blog of blasting

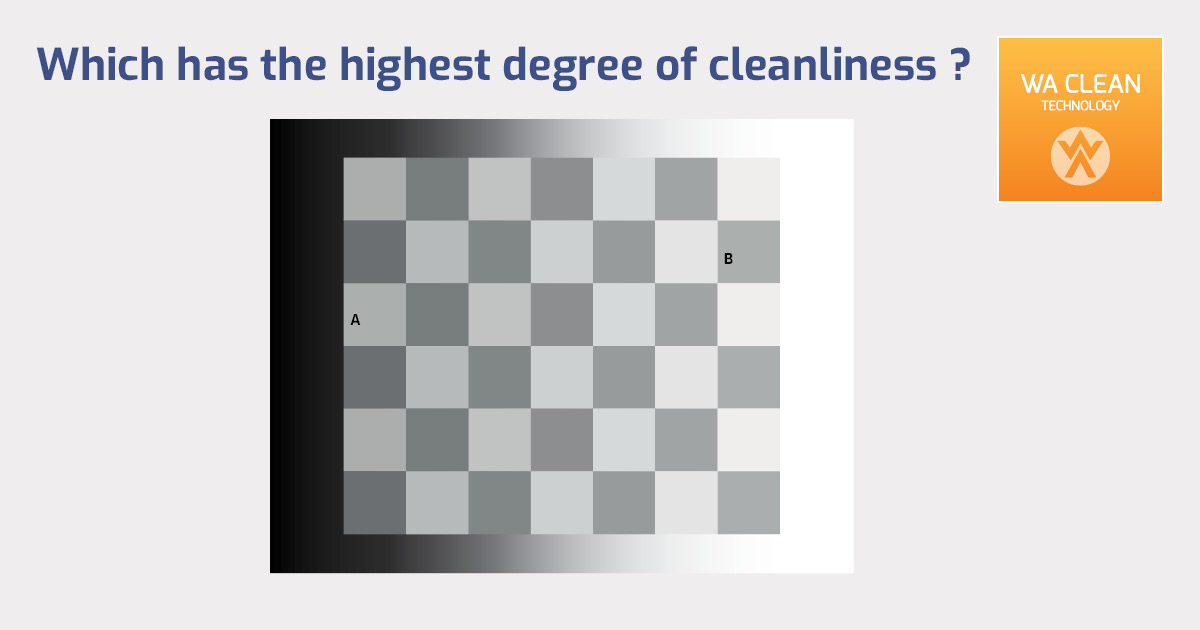

Do you have the eye to reduce your blasting costs?

We all know that the cleanliness of casted parts is subjective, and its degree has a large impact on productivity, shot consumption and blast...

Do you have the eye to reduce your blasting costs?

We all know that the cleanliness of casted parts is subjective, and its degree has a large impact on productivity, shot consumption and blast...

My Services and Solutions with W Abrasives

Toyo Seiko & Winoa, a new winning proposition for the cut wire shot peening market

When two worldwide leaders collaborate to bring a new winning proposition to the shot peening market.

Toyo Seiko Company manufactures a unique high durability conditioned...

My Services and Solutions with W Abrasives

Toyo Seiko & Winoa, a new winning proposition for the cut wire shot peening market

When two worldwide leaders collaborate to bring a new winning proposition to the shot peening market.

Toyo Seiko Company manufactures a unique high durability conditioned...

My innovation with WA

WA3D: It has never been easier to measure your surface profile.

Discover the first episode of WA Snapshot. The new series of W Abrasives that introduces you to its technologies and products in an easy to understand...

My innovation with WA

WA3D: It has never been easier to measure your surface profile.

Discover the first episode of WA Snapshot. The new series of W Abrasives that introduces you to its technologies and products in an easy to understand...

My services and solutions with WA

How about "TCO", W Abrasives truth about blasting costs ?

TCO "Total Cost of Ownership" is one of the WINOA's economic differentiation pillar.

Every action we do is guided by one concern: what is its real...

My services and solutions with WA

How about "TCO", W Abrasives truth about blasting costs ?

TCO "Total Cost of Ownership" is one of the WINOA's economic differentiation pillar.

Every action we do is guided by one concern: what is its real...

My Innovation with WA

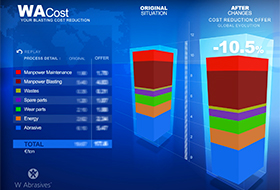

Launching of the WA COST App on iPhones

W Abrasives' main mission has always been to reduce the total cost of the blasting operation of its customers. It is in this sense that the WA COST technology, thanks...

My Innovation with WA

Launching of the WA COST App on iPhones

W Abrasives' main mission has always been to reduce the total cost of the blasting operation of its customers. It is in this sense that the WA COST technology, thanks...

My Services and Solutions with WA

Winoa improves Total Cost of Blasting with Hybrid Shot

Thanks to its 50 years of experience, Winoa is able to reduce its customers' blasting costs by offering a full technical approach: specific ranges of products, technologies...

My Services and Solutions with WA

Winoa improves Total Cost of Blasting with Hybrid Shot

Thanks to its 50 years of experience, Winoa is able to reduce its customers' blasting costs by offering a full technical approach: specific ranges of products, technologies...

My Success Story with WA

Success Story : Increase the performance of the blasting process

Increase the performance of the blasting process and reduce blasting cost in a manufacturing plant for articulated haulers

One of our famous Swedish customer manufactures...

My Success Story with WA

Success Story : Increase the performance of the blasting process

Increase the performance of the blasting process and reduce blasting cost in a manufacturing plant for articulated haulers

One of our famous Swedish customer manufactures...

My Success Story with WA

Success Story of blasting costs reduction at a cast iron foundry

A cast iron foundry customer is producing 800 tons per month of manholes and other miscellaneous parts for civil and road works. They are running a 16 wheel continuous...

My Success Story with WA

Success Story of blasting costs reduction at a cast iron foundry

A cast iron foundry customer is producing 800 tons per month of manholes and other miscellaneous parts for civil and road works. They are running a 16 wheel continuous...

My Success Story with WA

Hybrid Shot the perfect solution to reduce blasting cost in cleaning operations !

HYBRID SHOT the perfect solution to reduce blasting cost in cleaning operations !

The context

A cast iron foundry customer is producing...

My Success Story with WA

Hybrid Shot the perfect solution to reduce blasting cost in cleaning operations !

HYBRID SHOT the perfect solution to reduce blasting cost in cleaning operations !

The context

A cast iron foundry customer is producing...

My Success Story with WA

Success Story of Surface Protection for the Storbrücke Bridge, Hannover, Germany

Phenics, the Winoa revolutionary on-site abrasive blasting process, a successful challenge for the Storbrücke Bridge, Hannover, Germany

"We...

My Success Story with WA

Success Story of Surface Protection for the Storbrücke Bridge, Hannover, Germany

Phenics, the Winoa revolutionary on-site abrasive blasting process, a successful challenge for the Storbrücke Bridge, Hannover, Germany

"We...

Technology

The WA Cost Technology

More than 10 years ago, Winoa has developed a global blasting cost analysis technology: the WA COST. The main purpose of this technology is to identify cost reduction opportunities...

Technology

The WA Cost Technology

More than 10 years ago, Winoa has developed a global blasting cost analysis technology: the WA COST. The main purpose of this technology is to identify cost reduction opportunities...

Pipe Isolation Plant

"With W Abrasives we have decreased our blasting cost by 41%."

Vyacheslav works for Timashevk Pipe Isolation Plant (Russia). He testifies to the quality of W Abrasives’ products and services through which he was able to adjust...

Pipe Isolation Plant

"With W Abrasives we have decreased our blasting cost by 41%."

Vyacheslav works for Timashevk Pipe Isolation Plant (Russia). He testifies to the quality of W Abrasives’ products and services through which he was able to adjust...

My Success Story with W Abrasives

Success Story of our consulting service in Thailand

PREPARATION

Having received information that a new factory was being built in Thailand in the Chachoengsao region, and there were plans to install blasting...

My Success Story with W Abrasives

Success Story of our consulting service in Thailand

PREPARATION

Having received information that a new factory was being built in Thailand in the Chachoengsao region, and there were plans to install blasting...