The blog of blasting

The blog of blasting

Join us at the GIFA show in Düsseldorf

Join us at the GIFA show in Düsseldorf, Germany, from June 12th to 16th to see the future of surface preparation and blasting in the foundry,...

Join us at the GIFA show in Düsseldorf

Join us at the GIFA show in Düsseldorf, Germany, from June 12th to 16th to see the future of surface preparation and blasting in the foundry,...

MFN CEO Of america interview

The Tech Centre gives us a platform to not only demonstrate various solutions for our customers, it is also used for training of our ever changing customer base as well...

MFN CEO Of america interview

The Tech Centre gives us a platform to not only demonstrate various solutions for our customers, it is also used for training of our ever changing customer base as well...

Paintsquare: Ensuring a Successful Blasting Operation

Many factors impact your steel surface preparation, such as the type of coating, abrasive or shot blasting technique.

As experts for decades, we have developed technologies...

Paintsquare: Ensuring a Successful Blasting Operation

Many factors impact your steel surface preparation, such as the type of coating, abrasive or shot blasting technique.

As experts for decades, we have developed technologies...

_11zon.webp) The Importance of having a Balanced Operating Mix

One of the most important variables in the process of blast cleaning metal is keeping the Operating Mix balanced and maintaining all functions of a Blast...

The Importance of having a Balanced Operating Mix

One of the most important variables in the process of blast cleaning metal is keeping the Operating Mix balanced and maintaining all functions of a Blast...

W Care goes digital: discover how we provide remote consulting services

It’s no secret, covid crisis has highly impacted the way we work and provide services. However, as a solid service partner, Winoa experts have found a way to still...

W Care goes digital: discover how we provide remote consulting services

It’s no secret, covid crisis has highly impacted the way we work and provide services. However, as a solid service partner, Winoa experts have found a way to still...

A bespoke W Abrasives webinar for Jindal SAW Ltd.: continuously innovating client support

The meeting between 2 leaders on their own markets

Jindal SAW Ltd . is a global leader in the manufacture and supply of pipes that are primarily used for...

A bespoke W Abrasives webinar for Jindal SAW Ltd.: continuously innovating client support

The meeting between 2 leaders on their own markets

Jindal SAW Ltd . is a global leader in the manufacture and supply of pipes that are primarily used for...

The Blast Media Recovery System

What makes blasting with steel media cost effective is that the media can be used several times before it has broken down to the point that it is no longer effectively impacting...

The Blast Media Recovery System

What makes blasting with steel media cost effective is that the media can be used several times before it has broken down to the point that it is no longer effectively impacting...

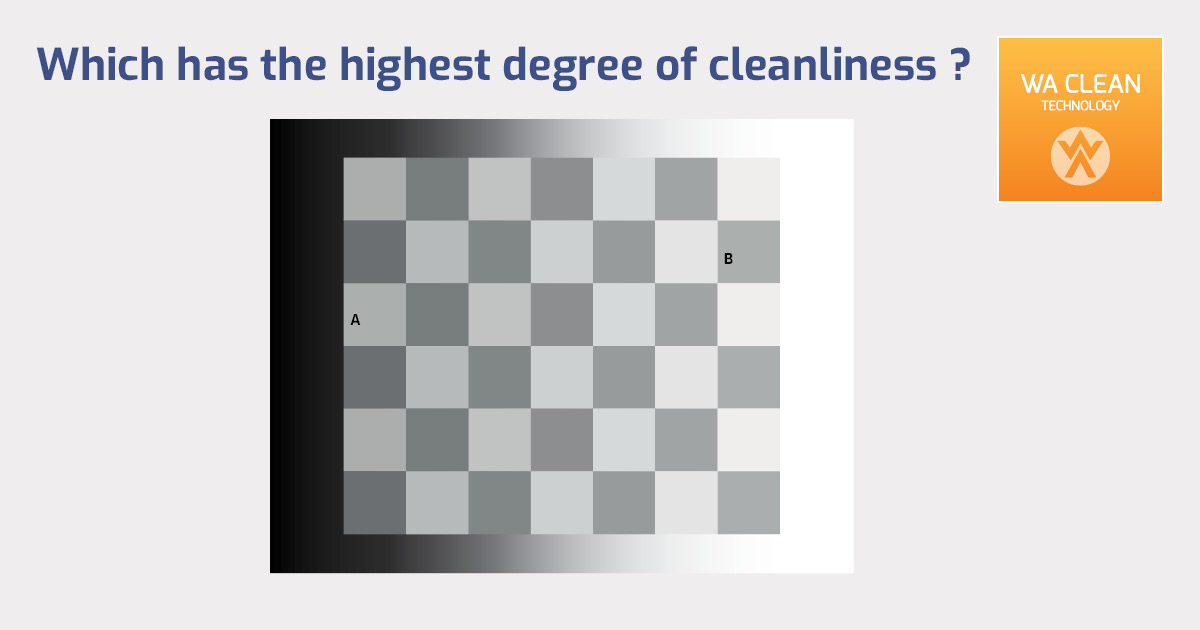

Do you have the eye to reduce your blasting costs?

We all know that the cleanliness of casted parts is subjective, and its degree has a large impact on productivity, shot consumption and blast...

Do you have the eye to reduce your blasting costs?

We all know that the cleanliness of casted parts is subjective, and its degree has a large impact on productivity, shot consumption and blast...

How Stanley Black & Decker significantly reduced their production costs with WA Clean.

Stanley Black & Decker , Lenox division, is recognized as World Leader in the manufacture of tools and saw blades. Following some production and quality challenges,...

How Stanley Black & Decker significantly reduced their production costs with WA Clean.

Stanley Black & Decker , Lenox division, is recognized as World Leader in the manufacture of tools and saw blades. Following some production and quality challenges,...

WA Clean Technology designated Product of the Year in the Surface Preparation Category by PaintSquare!

Developed by our engineers 4 years ago, the WA Clean technology evolved and grew!

Recently accredited by the International Organization for Standardization...

WA Clean Technology designated Product of the Year in the Surface Preparation Category by PaintSquare!

Developed by our engineers 4 years ago, the WA Clean technology evolved and grew!

Recently accredited by the International Organization for Standardization...

Why use Aluminum Oxide for shot blasting and surface preparation?

Aluminum oxide has long been a popular abrasive choice for sandblast and surface preparation when it is desired to avoid contamination and corrosion of parts.

However,...

Why use Aluminum Oxide for shot blasting and surface preparation?

Aluminum oxide has long been a popular abrasive choice for sandblast and surface preparation when it is desired to avoid contamination and corrosion of parts.

However,...

The 3 reasons why you should maintain your Separator ?

Often largely ignored or diminished in its importance, the separator system is a very crucial component of the blast machine. The reasons they are looked after less are...

The 3 reasons why you should maintain your Separator ?

Often largely ignored or diminished in its importance, the separator system is a very crucial component of the blast machine. The reasons they are looked after less are...

Why use Round Steel Shot for your surface preparation?

We often hear that it is dangerous to use grit in a Wheelblast machine. It seems that the grit would destroy the equipment and the life of the turbines.

However, we...

Why use Round Steel Shot for your surface preparation?

We often hear that it is dangerous to use grit in a Wheelblast machine. It seems that the grit would destroy the equipment and the life of the turbines.

However, we...

The blast cabinet

Seemingly the lowest maintenance area of a blast machine, the blast cabinet actually requires considerable care to maintain its integrity and prevent safety hazards. ...

The blast cabinet

Seemingly the lowest maintenance area of a blast machine, the blast cabinet actually requires considerable care to maintain its integrity and prevent safety hazards. ...

The magic of the Wheel

The Wheel

The workhorse of the whole wheel blasting operation is, of course, the wheel(s). All the other components of the machine, though no less important,...

The magic of the Wheel

The Wheel

The workhorse of the whole wheel blasting operation is, of course, the wheel(s). All the other components of the machine, though no less important,...

Event

W Abrasives at GIFA in Düsseldorf

W Abrasives @CastExpo in Atlanta

W Abrasives will be exhibiting at the CastExpo & Metalcasting Congress, April 27-30, in the Georgia World Congress Center,...

Event

W Abrasives at GIFA in Düsseldorf

W Abrasives @CastExpo in Atlanta

W Abrasives will be exhibiting at the CastExpo & Metalcasting Congress, April 27-30, in the Georgia World Congress Center,...

Event

W Abrasives at CastExpo in Atlanta

W Abrasives, a brand of Winoa Group, will attend the most important exhibition in the foundry sector, the GIFA trade show. It is taking place in Düsseldorf Germany,...

Event

W Abrasives at CastExpo in Atlanta

W Abrasives, a brand of Winoa Group, will attend the most important exhibition in the foundry sector, the GIFA trade show. It is taking place in Düsseldorf Germany,...

Breaking News

W Abrasives at ACPC, increase for all the Anti-Corrosion knowledge

The story started in 2012 when Winoa’s experts launched ACPC, an exclusive Consortium which gathers together specialists from different companies concerned by the...

Breaking News

W Abrasives at ACPC, increase for all the Anti-Corrosion knowledge

The story started in 2012 when Winoa’s experts launched ACPC, an exclusive Consortium which gathers together specialists from different companies concerned by the...

My Innovation with W Abrasives

WA Clean technology gets ISO Committee approval!

WA Clean is an exclusive technology developed by W Abrasives. This tool allows everyone to measure its cleanliness, thanks to a colorimetry process.

The incredible...

My Innovation with W Abrasives

WA Clean technology gets ISO Committee approval!

WA Clean is an exclusive technology developed by W Abrasives. This tool allows everyone to measure its cleanliness, thanks to a colorimetry process.

The incredible...

My Services and Solutions with W Abrasives

Toyo Seiko & Winoa, a new winning proposition for the cut wire shot peening market

When two worldwide leaders collaborate to bring a new winning proposition to the shot peening market.

Toyo Seiko Company manufactures a unique high durability conditioned...

My Services and Solutions with W Abrasives

Toyo Seiko & Winoa, a new winning proposition for the cut wire shot peening market

When two worldwide leaders collaborate to bring a new winning proposition to the shot peening market.

Toyo Seiko Company manufactures a unique high durability conditioned...

My Success Story with W Abrasives

Success Story of Hutchinson Paulstra, France

Hutchinson Paulstra is a French company specialized in the design and production of rubber-based anti-vibration and acoustic solutions. Its products are mainly aimed...

My Success Story with W Abrasives

Success Story of Hutchinson Paulstra, France

Hutchinson Paulstra is a French company specialized in the design and production of rubber-based anti-vibration and acoustic solutions. Its products are mainly aimed...

My innovation with WA

WA3D: It has never been easier to measure your surface profile.

Discover the first episode of WA Snapshot. The new series of W Abrasives that introduces you to its technologies and products in an easy to understand...

My innovation with WA

WA3D: It has never been easier to measure your surface profile.

Discover the first episode of WA Snapshot. The new series of W Abrasives that introduces you to its technologies and products in an easy to understand...

Breaking News

Interview of Pierre Coste, "Choosing the optimal steel abrasive: more than just shot and grit!

Choosing The Optimal Steel Abrasive: More Than Just Shot And Grit!

Come and see behind the scenes at WINOA - Gain insights that will help you to re-think your...

Breaking News

Interview of Pierre Coste, "Choosing the optimal steel abrasive: more than just shot and grit!

Choosing The Optimal Steel Abrasive: More Than Just Shot And Grit!

Come and see behind the scenes at WINOA - Gain insights that will help you to re-think your...

Breaking News

Winoa opens in Balmaseda (Spain) the world's most eco-friendly steel abrasives plant

Winoa opens in Balmaseda (Spain) the world’s most eco-friendly steel abrasives plant

October 3, 2018. The Winoa group is world leader in metal abrasives...

Breaking News

Winoa opens in Balmaseda (Spain) the world's most eco-friendly steel abrasives plant

Winoa opens in Balmaseda (Spain) the world’s most eco-friendly steel abrasives plant

October 3, 2018. The Winoa group is world leader in metal abrasives...

My Services and Solutions with WA

Tudoksad Seminar - we have customized solutions even for the most challenging customer needs!

On March 8th, Winoa, our Turkish agent Ekspert and Tudoksad - the Turkish Foundry Association organized a seminar dedicated to the steel and non-ferrous foundry sector....

My Services and Solutions with WA

Tudoksad Seminar - we have customized solutions even for the most challenging customer needs!

On March 8th, Winoa, our Turkish agent Ekspert and Tudoksad - the Turkish Foundry Association organized a seminar dedicated to the steel and non-ferrous foundry sector....

My Success Story with WA

Success Story, Why Linfen choose Stainium product ?

About our customer

In October 1998, Linfen Steel was restructured into “Taiyuan Iron Steel Co, LTD” which is also our customer. Now, business between...

My Success Story with WA

Success Story, Why Linfen choose Stainium product ?

About our customer

In October 1998, Linfen Steel was restructured into “Taiyuan Iron Steel Co, LTD” which is also our customer. Now, business between...

My innovation with WA

ACPC the 7th Consortium is building the future!

ACPC is the diminutive for ANTI CORROSION FOR PIPES COATING. The Consortium ACPC is a group of Specialists who aim to progress on Anti Corrosion knowledge, such as understanding,...

My innovation with WA

ACPC the 7th Consortium is building the future!

ACPC is the diminutive for ANTI CORROSION FOR PIPES COATING. The Consortium ACPC is a group of Specialists who aim to progress on Anti Corrosion knowledge, such as understanding,...

My success story with WA

Success Story of Transpnevmatika, provide an industrial solution to obtain a result of sufficient cleanliness.

Transpnevmatika is a major player in the production of railway equipment. The trust of its clients is based on such principles and fundamentals of collaboration as honesty,...

My success story with WA

Success Story of Transpnevmatika, provide an industrial solution to obtain a result of sufficient cleanliness.

Transpnevmatika is a major player in the production of railway equipment. The trust of its clients is based on such principles and fundamentals of collaboration as honesty,...

Breaking News

The 2018 Corrosion Trade Show and Conference in Arizona

The 2018 Corrosion Trade Show and Conference was held on April 15-19, 2018 at the Phoenix Convention Center in Phoenix AZ. The fair is hosted by NACE, which is a society...

Breaking News

The 2018 Corrosion Trade Show and Conference in Arizona

The 2018 Corrosion Trade Show and Conference was held on April 15-19, 2018 at the Phoenix Convention Center in Phoenix AZ. The fair is hosted by NACE, which is a society...

My services and solutions with WA

Adding WALUE to the blasting operations of Cleveland Bridge

Together with being a world leader in production of steel abrasives, Winoa Group also prides itself in being a leading service partner.

With technical expertise...

My services and solutions with WA

Adding WALUE to the blasting operations of Cleveland Bridge

Together with being a world leader in production of steel abrasives, Winoa Group also prides itself in being a leading service partner.

With technical expertise...

Breaking News

The SSPC 2018 in New Orleans

The Society for Protective Coatings Exhibition (SSPC 2018) was held January 15-18 at the Ernest N. Morial Convention Center in New Orleans, United States.

SSPC...

Breaking News

The SSPC 2018 in New Orleans

The Society for Protective Coatings Exhibition (SSPC 2018) was held January 15-18 at the Ernest N. Morial Convention Center in New Orleans, United States.

SSPC...

My innovation with WA

W Abrasives adds grit to its stainless range: Stelux CG

Its intrinsic characteristic, coupled with the excellent value for money settle the STELUX products as the best option for cleaning, deburring or surface preparation...

My innovation with WA

W Abrasives adds grit to its stainless range: Stelux CG

Its intrinsic characteristic, coupled with the excellent value for money settle the STELUX products as the best option for cleaning, deburring or surface preparation...

My services and solutions with WA

How about "TCO", W Abrasives truth about blasting costs ?

TCO "Total Cost of Ownership" is one of the WINOA's economic differentiation pillar.

Every action we do is guided by one concern: what is its real...

My services and solutions with WA

How about "TCO", W Abrasives truth about blasting costs ?

TCO "Total Cost of Ownership" is one of the WINOA's economic differentiation pillar.

Every action we do is guided by one concern: what is its real...

My success story with WA

Success Story of Bredero Shaw, Malaysia

Bredero Shaw is a division of ShawCor Ltd., a growth oriented, global energy services company specializing in technology-based products and services for the pipeline...

My success story with WA

Success Story of Bredero Shaw, Malaysia

Bredero Shaw is a division of ShawCor Ltd., a growth oriented, global energy services company specializing in technology-based products and services for the pipeline...

My success story with WA

Success Story: How to improve sealing efficiency and reduce safety risks in a bottom pour forging application?

How to improve sealing efficiency and reduce safety risks in a bottom pour forging application?

Once upon a time, in Canada, in the heart of Quebec, our experts...

My success story with WA

Success Story: How to improve sealing efficiency and reduce safety risks in a bottom pour forging application?

How to improve sealing efficiency and reduce safety risks in a bottom pour forging application?

Once upon a time, in Canada, in the heart of Quebec, our experts...

My success story with WA

Success Story of Wheelabrator Allevard Kurgan, excellent supplier

Our Russian sister company, Wheelabrator Allevard Kurgan has been honored by Transpneumatika Letter of excellence. This worldwide customer recognizes the quality of the...

My success story with WA

Success Story of Wheelabrator Allevard Kurgan, excellent supplier

Our Russian sister company, Wheelabrator Allevard Kurgan has been honored by Transpneumatika Letter of excellence. This worldwide customer recognizes the quality of the...

My Services and Solutions with WA

Training for shot blasting operations on turbine-powered machines

Winoa’s Testing Centers provide irrefutable proof that Winoa is much more than a manufacturer of shot media. Although the production of shot media remains its core...

My Services and Solutions with WA

Training for shot blasting operations on turbine-powered machines

Winoa’s Testing Centers provide irrefutable proof that Winoa is much more than a manufacturer of shot media. Although the production of shot media remains its core...

My Services and Solutions with WA

Trial in our Test Center with no limits. Seize the opportunity and reap the benefits!

Over and again customers have declined our offer to conduct trials, despite it being one of the fundamental steps in the Premium ‘7 Steps’ method. Over and...

My Services and Solutions with WA

Trial in our Test Center with no limits. Seize the opportunity and reap the benefits!

Over and again customers have declined our offer to conduct trials, despite it being one of the fundamental steps in the Premium ‘7 Steps’ method. Over and...

My success story with WA

Success Story : How to reduce abrasive consumption and machine wear for efficient cleaning of castings?

Technical Center in Houston, USA strengthens its position as expert in blasting solutions and furthers its reputation northwards, to Chattanooga, Tennessee.

...

My success story with WA

Success Story : How to reduce abrasive consumption and machine wear for efficient cleaning of castings?

Technical Center in Houston, USA strengthens its position as expert in blasting solutions and furthers its reputation northwards, to Chattanooga, Tennessee.

...

My Success Story with WA

Success Story: A successful long term partnership between the metal casting division of PSA Group and WINOA.

When considering these two groups, one can’t help but notice the similarity of their commitments: safety, quality, and environment, three points of focus that played...

My Success Story with WA

Success Story: A successful long term partnership between the metal casting division of PSA Group and WINOA.

When considering these two groups, one can’t help but notice the similarity of their commitments: safety, quality, and environment, three points of focus that played...

Breaking News with WA

Winoa cares about its customer satisfaction and supports UNICEF

Winoa cares about its customer satisfaction and supports UNICEF

If customer satisfaction is one of the main values advocated by Winoa, mutual aid and solidarity...

Breaking News with WA

Winoa cares about its customer satisfaction and supports UNICEF

Winoa cares about its customer satisfaction and supports UNICEF

If customer satisfaction is one of the main values advocated by Winoa, mutual aid and solidarity...

Breaking News with WA

Preparing tomorrow's surfaces: A new identity for Winoa

Preparing tomorrow’s surfaces: A new identity for Winoa

KPS Capital Partners, LP announced that it has signed a definitive agreement to...

Breaking News with WA

Preparing tomorrow's surfaces: A new identity for Winoa

Preparing tomorrow’s surfaces: A new identity for Winoa

KPS Capital Partners, LP announced that it has signed a definitive agreement to...

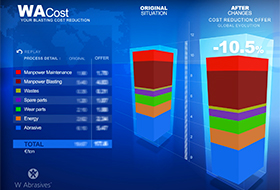

My Innovation with WA

Launching of the WA COST App on iPhones

W Abrasives' main mission has always been to reduce the total cost of the blasting operation of its customers. It is in this sense that the WA COST technology, thanks...

My Innovation with WA

Launching of the WA COST App on iPhones

W Abrasives' main mission has always been to reduce the total cost of the blasting operation of its customers. It is in this sense that the WA COST technology, thanks...

My Services and Solutions with WA

Winoa achieved certification from Bombardier, the world's leading manufacturer of both planes and trains.

Winoa is proud to announce that it has achieved certification from Bombardier, the world’s leading manufacturer of both planes and trains. Bombardier has extremely...

My Services and Solutions with WA

Winoa achieved certification from Bombardier, the world's leading manufacturer of both planes and trains.

Winoa is proud to announce that it has achieved certification from Bombardier, the world’s leading manufacturer of both planes and trains. Bombardier has extremely...

My Success Story with WA

Success Story : Profilium at the Service of Brazilian Agriculture

Despite the economic recession and a general downward trend of industry, agriculture is experiencing a boom and leads to recovery of agricultural machinery segment in...

My Success Story with WA

Success Story : Profilium at the Service of Brazilian Agriculture

Despite the economic recession and a general downward trend of industry, agriculture is experiencing a boom and leads to recovery of agricultural machinery segment in...

My Success Story with WA

Success Story of Prezioso Linjebygg & Phenics, a successful collaborative project

The French company Geosel (Geostock), specialists in underground hydrocarbon storage,entrusted the maintenance of the GSM 2 Sud pipeline to Prezioso Linjebygg, world...

My Success Story with WA

Success Story of Prezioso Linjebygg & Phenics, a successful collaborative project

The French company Geosel (Geostock), specialists in underground hydrocarbon storage,entrusted the maintenance of the GSM 2 Sud pipeline to Prezioso Linjebygg, world...

Breaking News with WA

Metalloobrabotka 2017, Russia

The 18th International Exhibition Metalloobrabotka was held from May 15 to 19, at the Expocentre in Moscow, Russia. During 5 days of exhibits, more than 980 exhibitors...

Breaking News with WA

Metalloobrabotka 2017, Russia

The 18th International Exhibition Metalloobrabotka was held from May 15 to 19, at the Expocentre in Moscow, Russia. During 5 days of exhibits, more than 980 exhibitors...

My Services and Solutions with WA

Wa Clean, surface cleanliness measurement tool

Some relevant technical magazines such as MFN, relay and highlight the Winoa’s technologies and know how :

>> Download the MFN article

...

My Services and Solutions with WA

Wa Clean, surface cleanliness measurement tool

Some relevant technical magazines such as MFN, relay and highlight the Winoa’s technologies and know how :

>> Download the MFN article

...

My Services and Solutions with WA

Winoa improves Total Cost of Blasting with Hybrid Shot

Thanks to its 50 years of experience, Winoa is able to reduce its customers' blasting costs by offering a full technical approach: specific ranges of products, technologies...

My Services and Solutions with WA

Winoa improves Total Cost of Blasting with Hybrid Shot

Thanks to its 50 years of experience, Winoa is able to reduce its customers' blasting costs by offering a full technical approach: specific ranges of products, technologies...

My Success Story with WA

Success Story : Increase the performance of the blasting process

Increase the performance of the blasting process and reduce blasting cost in a manufacturing plant for articulated haulers

One of our famous Swedish customer manufactures...

My Success Story with WA

Success Story : Increase the performance of the blasting process

Increase the performance of the blasting process and reduce blasting cost in a manufacturing plant for articulated haulers

One of our famous Swedish customer manufactures...

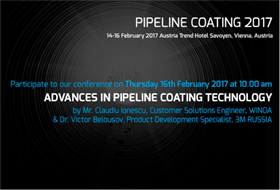

Breaking News With WA

Pipeline Coating Conference 2017 in Vienna

The Pipeline Coating Conference was held in Vienna, from 15th to 16th February 2017.

This conference is one of the two major international events...

Breaking News With WA

Pipeline Coating Conference 2017 in Vienna

The Pipeline Coating Conference was held in Vienna, from 15th to 16th February 2017.

This conference is one of the two major international events...

Breaking News with WA

The SSPC 2017 in Florida

Tampa, Florida – USA

January 30 – February 02, 2017

The SSPC 2017 was held from January 30 to February 02, at the Tampa Convention...

Breaking News with WA

The SSPC 2017 in Florida

Tampa, Florida – USA

January 30 – February 02, 2017

The SSPC 2017 was held from January 30 to February 02, at the Tampa Convention...

My Success Story with WA

Success Story of Nietiedt Oberflächentechnik Hamburg, Germany

The Project

Nietiedt Oberflächentechnik Hamburg is one of the leading specialists in heavy corrosion protection in Germany. In addition to the marine corrosion...

My Success Story with WA

Success Story of Nietiedt Oberflächentechnik Hamburg, Germany

The Project

Nietiedt Oberflächentechnik Hamburg is one of the leading specialists in heavy corrosion protection in Germany. In addition to the marine corrosion...

My Success Story with WA

Success Story of blasting costs reduction at a cast iron foundry

A cast iron foundry customer is producing 800 tons per month of manholes and other miscellaneous parts for civil and road works. They are running a 16 wheel continuous...

My Success Story with WA

Success Story of blasting costs reduction at a cast iron foundry

A cast iron foundry customer is producing 800 tons per month of manholes and other miscellaneous parts for civil and road works. They are running a 16 wheel continuous...

My Services and Solutions with WA

How IKB Test Center Impressed Petrobras?

How IKB Test Center Impressed Petrobras?

one of our distributors in the Brazilian market, has developed a portable line of turbines called Mini Ecus,...

My Services and Solutions with WA

How IKB Test Center Impressed Petrobras?

How IKB Test Center Impressed Petrobras?

one of our distributors in the Brazilian market, has developed a portable line of turbines called Mini Ecus,...

My Services and Solutions with WA

October 2016, the 6th seminar Consortium "Anti-corrosion pipe coating" took place in Russia

The 3-6 th of October 2016, the 6th seminar “Consortium “Anti-corrosion pipe coating” took place in Sergiev Possad city. 46 participants from the 25...

My Services and Solutions with WA

October 2016, the 6th seminar Consortium "Anti-corrosion pipe coating" took place in Russia

The 3-6 th of October 2016, the 6th seminar “Consortium “Anti-corrosion pipe coating” took place in Sergiev Possad city. 46 participants from the 25...

My Success Story with WA

Success Story of Daewoo Shipbuilding & Marine Engineering (DSME) for ship's outside blasting surface

Daewoo Shipbuilding & Marine Engineering (DSME) won the tender to build 15 ice breakers to transport liquefied natural gas (LNG) for Russia’s Yamal project...

My Success Story with WA

Success Story of Daewoo Shipbuilding & Marine Engineering (DSME) for ship's outside blasting surface

Daewoo Shipbuilding & Marine Engineering (DSME) won the tender to build 15 ice breakers to transport liquefied natural gas (LNG) for Russia’s Yamal project...

My Services and Solutions with WA

A new identity for Phenics machines

A new identity for Phenics machines

Phenics, the Winoa’s new system which transforms traditional site blasting by enabling...

My Services and Solutions with WA

A new identity for Phenics machines

A new identity for Phenics machines

Phenics, the Winoa’s new system which transforms traditional site blasting by enabling...

My Success Story with WA

Success of Baosteel: the benefits to use Stainum Premium Product

The benefits to use Stainum Premium Product

Baosteel is the 3rd biggest crude steel producer in the world and the 2nd biggest customer of SMS (Shanghai...

My Success Story with WA

Success of Baosteel: the benefits to use Stainum Premium Product

The benefits to use Stainum Premium Product

Baosteel is the 3rd biggest crude steel producer in the world and the 2nd biggest customer of SMS (Shanghai...

My Success Story with WA

Hybrid Shot the perfect solution to reduce blasting cost in cleaning operations !

HYBRID SHOT the perfect solution to reduce blasting cost in cleaning operations !

The context

A cast iron foundry customer is producing...

My Success Story with WA

Hybrid Shot the perfect solution to reduce blasting cost in cleaning operations !

HYBRID SHOT the perfect solution to reduce blasting cost in cleaning operations !

The context

A cast iron foundry customer is producing...

Breaking News with WA

Customers technical seminar in Dubai

Thanks to its complete range of innovative solutions, Winoa keeps a step ahead in your blasting operations.

In May 2016, WInoa and its leader brand,...

Breaking News with WA

Customers technical seminar in Dubai

Thanks to its complete range of innovative solutions, Winoa keeps a step ahead in your blasting operations.

In May 2016, WInoa and its leader brand,...

Breaking News with WA

Granite cutting customers seminar in Brazil

Winoa offers its granite cutting customers a seminar in Brazil.

WINOA organized a seminar for our Brazilian customers, users of gang-saw machines, introducing...

Breaking News with WA

Granite cutting customers seminar in Brazil

Winoa offers its granite cutting customers a seminar in Brazil.

WINOA organized a seminar for our Brazilian customers, users of gang-saw machines, introducing...

My Success Story with WA

Success Story of Brass Technics Systems,how increase productivity without changing the surface appearance

Brass Technics Systems was founded in 1992 in Lumezzane in Lombardy for the production of brass components based on customer design using mechanical machining. Their...

My Success Story with WA

Success Story of Brass Technics Systems,how increase productivity without changing the surface appearance

Brass Technics Systems was founded in 1992 in Lumezzane in Lombardy for the production of brass components based on customer design using mechanical machining. Their...

My Innovation with WA

WA CLEAN your exclusive measuring device!

WA CLEAN your exclusive measuring device!

A technology developed by W Abrasives to facilitate the application...

My Innovation with WA

WA CLEAN your exclusive measuring device!

WA CLEAN your exclusive measuring device!

A technology developed by W Abrasives to facilitate the application...

My Success Story with WA

Success Story of Surface Protection for the Storbrücke Bridge, Hannover, Germany

Phenics, the Winoa revolutionary on-site abrasive blasting process, a successful challenge for the Storbrücke Bridge, Hannover, Germany

"We...

My Success Story with WA

Success Story of Surface Protection for the Storbrücke Bridge, Hannover, Germany

Phenics, the Winoa revolutionary on-site abrasive blasting process, a successful challenge for the Storbrücke Bridge, Hannover, Germany

"We...

My Success Story with WA

Why the leading shipbuilding company in Taiwan, CSBC, chooses the W Abrasives HPG Premium product ?

Why the leading shipbuilding company in Taiwan, CSBC, chooses the W Abrasives HPG Premium product ?

CSBC (China Shipbuilding Company) is the leading...

My Success Story with WA

Why the leading shipbuilding company in Taiwan, CSBC, chooses the W Abrasives HPG Premium product ?

Why the leading shipbuilding company in Taiwan, CSBC, chooses the W Abrasives HPG Premium product ?

CSBC (China Shipbuilding Company) is the leading...

My Innovation with WA

For coating lifetime enfacement, choose the premium product Surfium

SURFIUM a premium W Abrasives product for coating lifetime enfacement.

Since mid – 2014, W Abrasives developed a turnkey solution called Surf...

My Innovation with WA

For coating lifetime enfacement, choose the premium product Surfium

SURFIUM a premium W Abrasives product for coating lifetime enfacement.

Since mid – 2014, W Abrasives developed a turnkey solution called Surf...

My Success Story with WA

Phenics Air, the new unit for non road access or altitude sites

PHENICS is in the air now!

A new member has joined the Phenics machine fleet...

In addition to Phenics Combi and Phenics XL, we have...

My Success Story with WA

Phenics Air, the new unit for non road access or altitude sites

PHENICS is in the air now!

A new member has joined the Phenics machine fleet...

In addition to Phenics Combi and Phenics XL, we have...

My Success Story with WA

Why Metal Coating Industries (MCI) choosed Surfium ?

SURFIUM@METAL COATING INDUSTRIES, ABU DHABI, November 1, 2015

Interview with Mr. Ayman Tannourah (AT), Plant Operations Manager, MCI by Sunil...

My Success Story with WA

Why Metal Coating Industries (MCI) choosed Surfium ?

SURFIUM@METAL COATING INDUSTRIES, ABU DHABI, November 1, 2015

Interview with Mr. Ayman Tannourah (AT), Plant Operations Manager, MCI by Sunil...

Pictures

The GIFA 2015 movie

Pictures

The GIFA 2015 movie

Innovation

The maintenance Pack

Beyond the well-known Premium services (testing, training and consulting solutions) which are coming along with Premium products, Winoa is now bringing to its customers a...

Innovation

The maintenance Pack

Beyond the well-known Premium services (testing, training and consulting solutions) which are coming along with Premium products, Winoa is now bringing to its customers a...

Technology

The WA Cost Technology

More than 10 years ago, Winoa has developed a global blasting cost analysis technology: the WA COST. The main purpose of this technology is to identify cost reduction opportunities...

Technology

The WA Cost Technology

More than 10 years ago, Winoa has developed a global blasting cost analysis technology: the WA COST. The main purpose of this technology is to identify cost reduction opportunities...

My success story with W Abrasives

Czech success story on stelux field

One of our biggest Czech wheel manufacturers has recently met The Winoa Representatives to discuss the possibility of becoming their worldwide supplier. They expressed...

My success story with W Abrasives

Czech success story on stelux field

One of our biggest Czech wheel manufacturers has recently met The Winoa Representatives to discuss the possibility of becoming their worldwide supplier. They expressed...

My innovation with W Abrasives

Animation 3D roughness

W Abrasives launches a new animation to promote its Surf Prep Pack offer and its Surfium range. This animation details the blasting operation steps.

...

My innovation with W Abrasives

Animation 3D roughness

W Abrasives launches a new animation to promote its Surf Prep Pack offer and its Surfium range. This animation details the blasting operation steps.

...

My Innovation with W Abrasives

Discover the new W Abrasives technologies

The blasting process is well known for surface cleaning and surface preparation due to its high efficiency and major enhancement of surface properties before coating:...

My Innovation with W Abrasives

Discover the new W Abrasives technologies

The blasting process is well known for surface cleaning and surface preparation due to its high efficiency and major enhancement of surface properties before coating:...

My Success Story with W Abrasives

10 years of a win-win partnership

Our loyal customer Beltramo, located in the province of Cuneo near Turin in Italy, is celebrating 10 years of processing with the large granite-cutting gangsaw machine....

My Success Story with W Abrasives

10 years of a win-win partnership

Our loyal customer Beltramo, located in the province of Cuneo near Turin in Italy, is celebrating 10 years of processing with the large granite-cutting gangsaw machine....

Izhorsky Pipes Plant

"We associate the W Abrasives brand name with high product quality and high level of technical support."

Nikolay Orlov is Purchasing Manager for Izhorsky Pipes Plant. The quality of W Abrasives products and the efficiency of its customer service enable them to work confidently...

Izhorsky Pipes Plant

"We associate the W Abrasives brand name with high product quality and high level of technical support."

Nikolay Orlov is Purchasing Manager for Izhorsky Pipes Plant. The quality of W Abrasives products and the efficiency of its customer service enable them to work confidently...

Vyksa Steel Works

"W Abrasives products differ from other in terms of high and constant quality."

Sergey Biryukov is anti-corrosion manager at Vyksa Steel Works. He outlines the key role of W Abrasives during surface preparation in the coating process.

For him, the...

Vyksa Steel Works

"W Abrasives products differ from other in terms of high and constant quality."

Sergey Biryukov is anti-corrosion manager at Vyksa Steel Works. He outlines the key role of W Abrasives during surface preparation in the coating process.

For him, the...

Pipe Isolation Plant

"With W Abrasives we have decreased our blasting cost by 41%."

Vyacheslav works for Timashevk Pipe Isolation Plant (Russia). He testifies to the quality of W Abrasives’ products and services through which he was able to adjust...

Pipe Isolation Plant

"With W Abrasives we have decreased our blasting cost by 41%."

Vyacheslav works for Timashevk Pipe Isolation Plant (Russia). He testifies to the quality of W Abrasives’ products and services through which he was able to adjust...

The Nuova Italiana experience about Cosmos system

The company Nuova Italiana has installed the COSMOS system proposed by Winoa. Which are the reasons which lead you to this decision?

We know very well Winoa since...

The Nuova Italiana experience about Cosmos system

The company Nuova Italiana has installed the COSMOS system proposed by Winoa. Which are the reasons which lead you to this decision?

We know very well Winoa since...

My Success Story with W Abrasives

10% reduction in blasting costs for Vacuumschmelze

Vacuumschmelze is one of our German customers which has worldwide production locations based in Slovakia, China, Asia, USA, as well as sales offices in...

My Success Story with W Abrasives

10% reduction in blasting costs for Vacuumschmelze

Vacuumschmelze is one of our German customers which has worldwide production locations based in Slovakia, China, Asia, USA, as well as sales offices in...

My Success story With W Abrasives

Supplier of The Year Award for Best Innovation Performance

Best Innovation Performance

As a fitting testimony to a successful partnership, IKK do Brasil/W Abrasives was recently awarded the Supplier of The Year Award for...

My Success story With W Abrasives

Supplier of The Year Award for Best Innovation Performance

Best Innovation Performance

As a fitting testimony to a successful partnership, IKK do Brasil/W Abrasives was recently awarded the Supplier of The Year Award for...

Breaking News from W Abrasives

A concrete example of eco responsibility

Winoa confirms its commitment as a responsible industry that is well integrated into its environment. The site at Le Cheylas, which has ISO 14001 quality and environment...

Breaking News from W Abrasives

A concrete example of eco responsibility

Winoa confirms its commitment as a responsible industry that is well integrated into its environment. The site at Le Cheylas, which has ISO 14001 quality and environment...

My Services & Solutions from W Abrasives

A New Packaging for the Premium Range

Packaging, like the product itself, is a key component of any offering, and as such it is one of Winoa’s key priorities. In January 2012, the group launched new...

My Services & Solutions from W Abrasives

A New Packaging for the Premium Range

Packaging, like the product itself, is a key component of any offering, and as such it is one of Winoa’s key priorities. In January 2012, the group launched new...

My Success Story with W Abrasives

Success Story of our consulting service in Thailand

PREPARATION

Having received information that a new factory was being built in Thailand in the Chachoengsao region, and there were plans to install blasting...

My Success Story with W Abrasives

Success Story of our consulting service in Thailand

PREPARATION

Having received information that a new factory was being built in Thailand in the Chachoengsao region, and there were plans to install blasting...